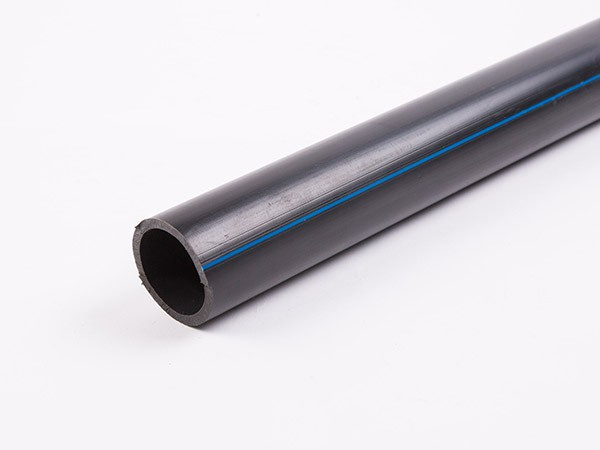

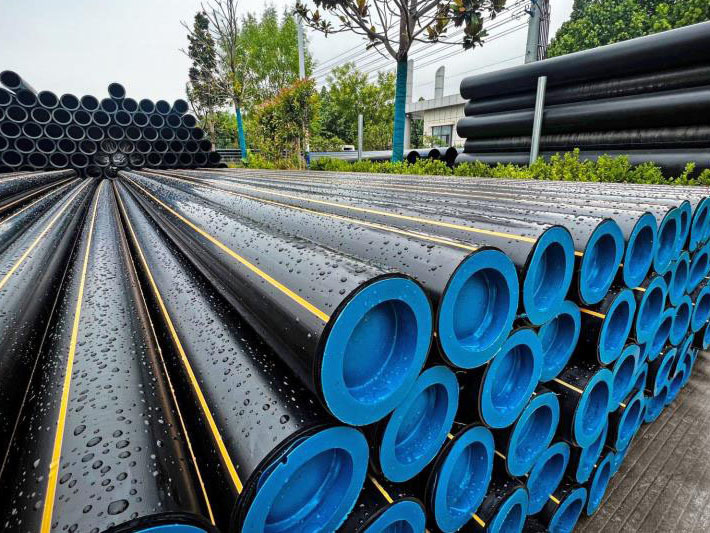

Product display

PE water supply pipe-pe pipe manufacturers

The principle of PE pipe extrusion involves polymer chemistry, polymer physics, interface theory, plastic machinery, plastic processing mold, formula design principle and process control. Extrusion theory mainly studies the movement and variation of plastics in the extruder. Extruder plastic under a certain external force, in different temperature range of the three physical state of the polymer, and the screw structure, plastic properties, the relationship between the processing conditions. So as to carry out reasonable process control. In order to achieve the purpose of improving the output and quality of plastic products. Plastic polymer materials, when heated under constant pressure, in different temperature ranges, there are three physical states: glass state, high elastic state and viscous flow state. Generally, the molding temperature of plastics is above the viscous flow temperature.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

pe pipe extrusion principle

The plastics processing industry is a highly comprehensive technology-based industry.

The principle of PE pipe extrusion involves polymer chemistry, polymer physics, interface theory, plastic machinery, plastic processing mold, formula design principle and process control. Extrusion theory mainly studies the movement and variation of plastics in the extruder. Extruder plastic under a certain external force, in different temperature range of the three physical state of the polymer, and the screw structure, plastic properties, the relationship between the processing conditions. So as to carry out reasonable process control. In order to achieve the purpose of improving the output and quality of plastic products. Plastic polymer materials, when heated under constant pressure, in different temperature ranges, there are three physical states: glass state, high elastic state and viscous flow state. Generally, the molding temperature of plastics is above the viscous flow temperature.

The rotation of the screw generates shear force to break the plastic. The rotation of the screw generates driving force to make the broken plastic advance continuously and thus generate extrusion pressure. Under the action of extrusion pressure, the filter plate and other parts of the pressure generate reaction force (I. e. back pressure), resulting in the flow and stirring of the plastic, thus realizing the overall balance of the extrusion process. This process is the necessary and sufficient condition for the uniform plasticization of plastics.

HDPE is a high crystallinity, non-polar thermoplastic resin. High density polyethylene is a white powder granular product, non-toxic, tasteless, density in the range of 0.940~0.976g/cm3; The crystallinity is 80% ~ 90%, the softening point is 125~135 ℃, and the service temperature can reach 100 ℃. The melting temperature is 120~160 ℃. For materials with larger molecules, the recommended melting temperature range is 200~250 ℃. It has good heat resistance and cold resistance, good chemical stability, high rigidity and toughness, and good mechanical strength. Dielectric properties, environmental stress cracking resistance is also good. Hardness, tensile strength and creep are better than low density polyethylene. Wear resistance, electrical insulation, toughness and cold resistance are better, but slightly worse than low density insulation. Good chemical stability, insoluble in any organic solvent at room temperature, corrosion resistance to acid, alkali and various salts; The film has small permeability to water vapor and air and low water absorption. Poor aging resistance and inferior environmental cracking resistance to low density polyethylene, in particular, thermal oxidation will reduce its performance, so the resin needs to add antioxidants and ultraviolet absorbers to improve this aspect. High density polyethylene film in the case of low thermal deformation temperature, this point should be paid attention to when the application.

Previous Page

Next Page

Previous Page

Next Page

Product inquiry