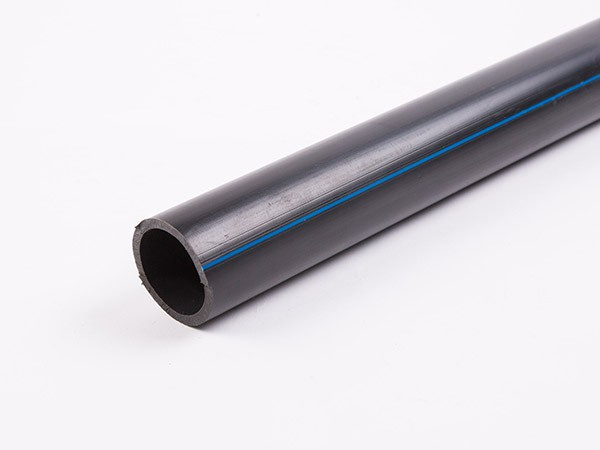

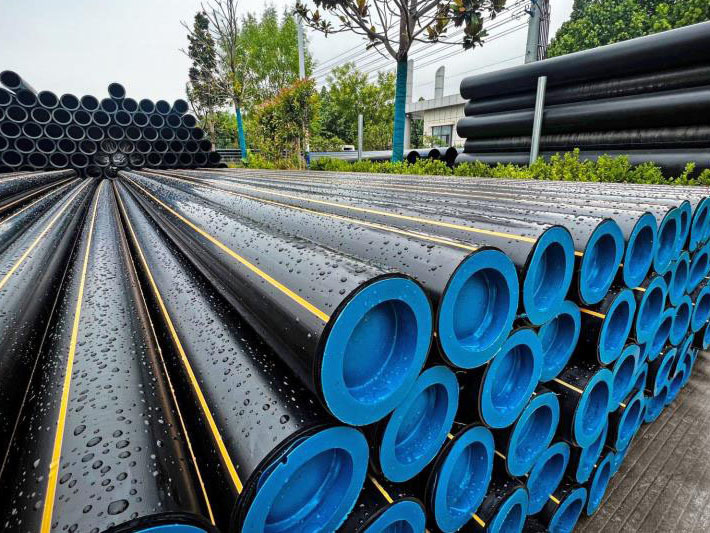

Product display

PE gas pipe

Products have been widely used in environmental protection, papermaking, metallurgy, electric power, mining, chemical fiber, petrochemical, sulfuric acid, chlor-alkali, pharmaceutical, salinization, landfill and sewage treatment and other fields.

Classification:

PE gas pipe

Key words:

Hotline:

Product Description

PE gas pipe is made of polyethylene mixed ingredients. The problems of corrosion and joint leakage of steel pipes and cast iron pipes will be completely solved, thus ensuring the safe operation of the gas pipeline network system. The PE material selected for PE gas pipe is inert material, which can resist the erosion of various chemical media. The pipe wall has low friction coefficient, small flow resistance and strong conveying capacity. It is connected by electric melting. The joint strength is higher than that of the pipe body. The elongation at break of high toughness PE generally exceeds 500. PE gas pipe has good seismic performance, resistance to slow crack growth (SCG), rapid crack growth (RCP), flexibility and scratch resistance.

PE gas pipe has very strong adaptability to uneven settlement of pipe base and strong wear resistance, which is fully in line with the national "GB/T15558.1-2015" standard. A variety of non-excavation methods can be used, which greatly facilitates the construction and installation of the work, the system cost is low, the maintenance cost is low, and the project cost can be greatly reduced.

Application areas

Buried polyethylene (PE) pipelines for gas are suitable for buried urban gas pipeline systems with a working temperature of-20-40C and a maximum allowable working pressure of not more than 0.7MPa. Types of gas suitable for transportation:

1, natural gas: such as pure natural gas, oil associated gas, mine gas, etc;

2, artificial gas: such as coke oven gas, water gas, oil gas, blast furnace gas, etc;

3. Liquefied petroleum gas;

4, biogas.

Product Performance

Reliable connection

Polyethylene piping systems are connected by electrical melting, and the strength of the joint is higher than that of the pipe body.

good stress cracking resistance

PE gas pipe has low notch sensitivity, high shear strength and excellent scratch resistance, environmental stress cracking resistance is also very outstanding.

Aging resistance, long service life

Polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored or used outdoors in the open for 50 years without being damaged by ultraviolet radiation.

Good low temperature impact resistance

The low-temperature embrittlement temperature of polyethylene is extremely low, and it can be used safely in the temperature range of-60-60C. During winter construction, the material has good impact resistance and will not cause pipe embrittlement.

Easy handling

PE gas pipe is lighter than concrete pipe, galvanized pipe and steel pipe, it is easy to handle and install, lower manpower and equipment requirements, means that the installation cost of the project is greatly reduced.

good wear resistance

The comparative test of wear resistance between PE gas pipe and steel pipe shows that the wear resistance of HDPE pipe is 4 times that of steel pipe. HDPE pipe has longer service life and better economy.

Product inquiry