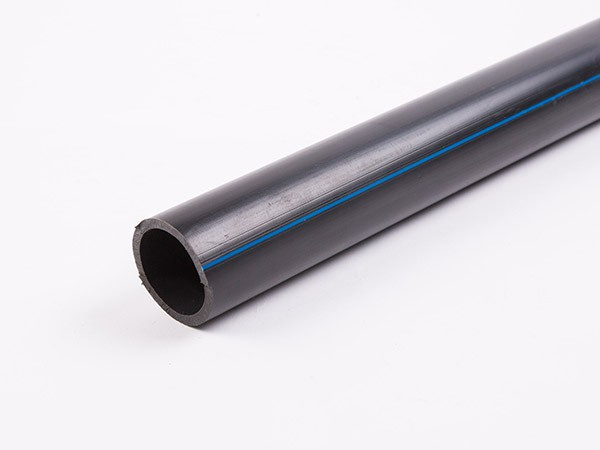

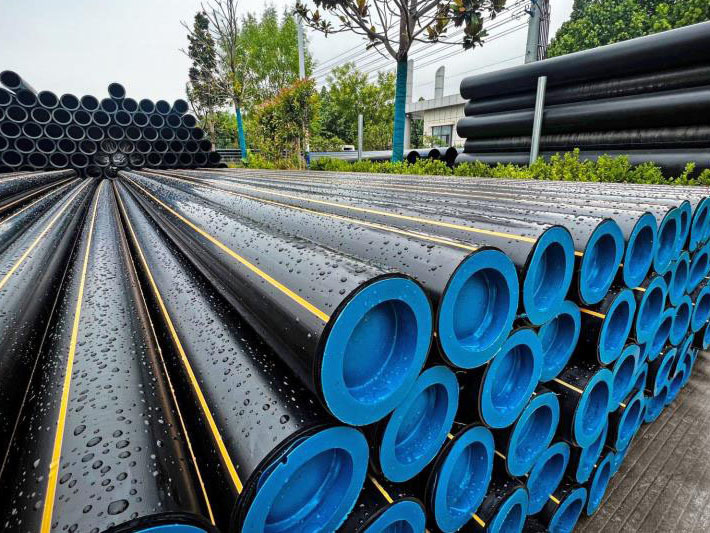

Product display

PE water supply pipe-PE pipe

Products have been widely used in environmental protection, papermaking, metallurgy, electric power, mining, chemical fiber, petrochemical, sulfuric acid, chlor-alkali, pharmaceutical, salinization, landfill and sewage treatment and other fields.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

PE Pipe Classification

PE pipe according to the pipe density points: high density polyethylene pipe, medium density polyethylene pipe, low density polyethylene pipe;

PE pipe according to the pipe structure: smooth wall polyethylene pipe, double wall corrugated polyethylene pipe, spiral wound polyethylene pipe;

PE pipe according to the pipe material points: cross-linked polyethylene pipe, aluminum-plastic composite polyethylene pipe, copper-plastic composite polyethylene pipe, steel-plastic composite polyethylene pipe;

PE pipes are divided into water supply and drainage pipes, gas pipes, electrical casing pipes, agricultural pipes, industrial pipes, hot water heating pipes, and sewage pipes;

PE pipe specification

PE pipe grade: PE32, PE40, PE63, PE80, PE100

Standard size ratio (ratio of nominal outer diameter to nominal wall thickness):SDR26, SDR21, SDR17.6, SDR13.6, SDR11

Nominal pressure (MPa):0.4, 0.6, 0.8, 1.0, 1.25, 1.6

PE80 vs. PE100

PE80 and PE100 are the basic resins for the production of pressure-bearing plastic pipes, especially PE100 is the only polyethylene grade in the high-pressure pressure pipeline at home and abroad, which can be widely used in pressure-bearing water pipes, gas pipes and various industrial pipes. PE100 has excellent melt fluidity, weather resistance and long-term stability. As a raw material, the pressure-bearing pipeline produced can guarantee 50 years of service life under the conditions of 8.0MPa and 20 ℃.

The MRS of PE80 is 8MPa; The MRS of PE100 reaches 10MPa(MRS refers to the hoop tensile stress strength of the pipe). At the same working pressure, the wall thickness of the PE100 pipe is thinner, and the density of the two materials is very close.

"Buried Polyethylene (PE) Pipeline System for Gas Part 1: Pipes" GB 15558.1-2003 stipulates that PE pipe series are divided into SDR11 and SDR17.6 series according to standard size ratio (SDR).

For urban natural gas pipelines, when the design pressure of the pipeline is 0.4MPa (medium pressure A grade of urban gas pipelines), SDR11 series must be used for PE80 pipes, while SDR17.6 series can be used for PE100 pipes.

Under the premise of ensuring the performance, it can greatly reduce the consumption of PE raw materials and reduce the cost. Using PE100 instead of PE80 material, material consumption can be reduced by about 35%, material costs can be saved by about 20%.

Previous Page

Previous Page

Product inquiry