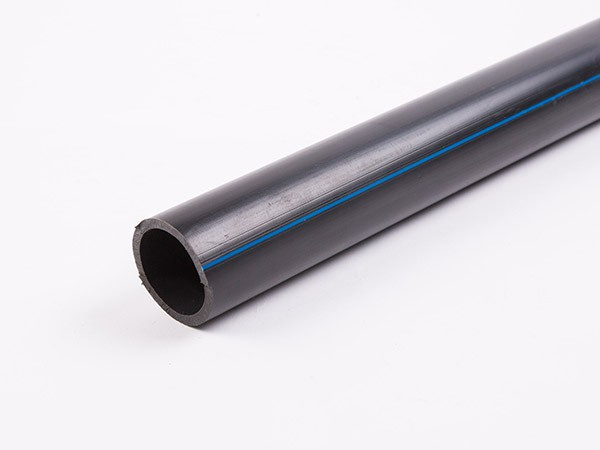

Product display

PE water supply pipe-PE pipe supply

The inner wall of PE pipe is smooth and does not scale. Compared with metal pipes, PE pipes can reduce the project investment by about 1/3, and can be coiled with small-diameter pipes, which can further reduce the project cost.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

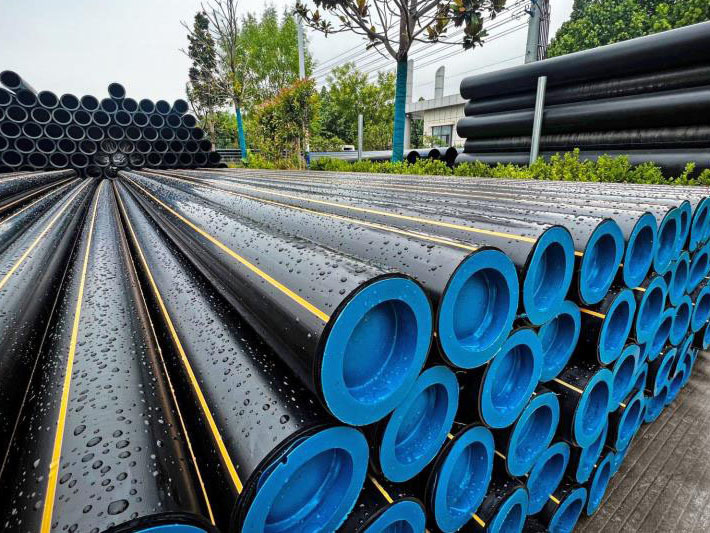

PE pipe overcomes the shortcomings of galvanized pipe and cast iron pipe that are easy to rust, scale, breed bacteria, and have a short life; it has the characteristics of reliable quality, safe operation, convenient maintenance, and economical cost. In particular, the hot melt process of PE water supply pipe is more suitable The direct burial and concealed burial of the pipeline effectively solve the problem of joint leakage.

In the municipal water supply project, PE pipe has become the pipe field of "plastic instead of steel" pipe. What are its advantages and characteristics?

NO.01

Excellent physical properties of PE pipe

PE pipe not only maintains the rigidity and strength of high-density polyethylene, but also has good flexibility and creep resistance, and the higher-density polyethylene has the characteristics of excellent hot melt connection performance, which is conducive to the installation of plastic pipes.

NO.02

PE pipeline corrosion resistance, no scaling

PE water supply pipe is a kind of polymer material with non-polar structure, which has the ability of anti-acid and alkali corrosion, no rust, no scaling, aging resistance, no breeding of microorganisms, no peculiar smell, is the ideal pipe for drinking water transportation.

NO.03

Good toughness and flexibility of PE pipe

PE pipe is a kind of high toughness pipe, which has strong adaptability to uneven settlement and dislocation of pipe foundation and good seismic resistance. Practice around the world has proved that PE pipe is a good seismic resistance pipe.

NO.04

Large circulation capacity, economically cost-effective

The inner wall of PE pipe is smooth and does not scale. Compared with metal pipes, PE pipes can reduce the project investment by about 1/3, and can be coiled with small-diameter pipes, which can further reduce the project cost.

NO.05

Convenient connection, simple construction, diverse methods

PE pipe is light, easy to handle, easy to weld, less welding ports, when the pipeline is long, coil can be used for laying, PE pipe trench requirements are far lower than steel pipe trench requirements, and when the construction conditions are limited, electric fusion welding can be used.

NO.06

light weight

The quality is only 1/10 of the steel, which can greatly reduce the construction intensity of workers and reduce the lifting cost of machinery.

NO.07

Long service life easy to recycle

PE pipe service life of up to 50 years, easy to recycle, will not produce substances that have an impact on the environment, mature technology and continuous development.

NO.08

5cm per second

It has strong adaptability to the change of foundation. PE pipe is a kind of high toughness pipe, its elongation at break is generally more than 50%, the ability to adapt to uneven settlement of the pipe base is very strong, and it has effective resistance to foundation settlement and end load.

NO.09

Easy maintenance

Maintenance and installation can be made without water and gas shutdown.

NO.10

good stress cracking resistance

PE pipe has low notch sensitivity, environmental stress resistance is very prominent, low temperature impact resistance is good.

Previous Page

Previous Page

Product inquiry