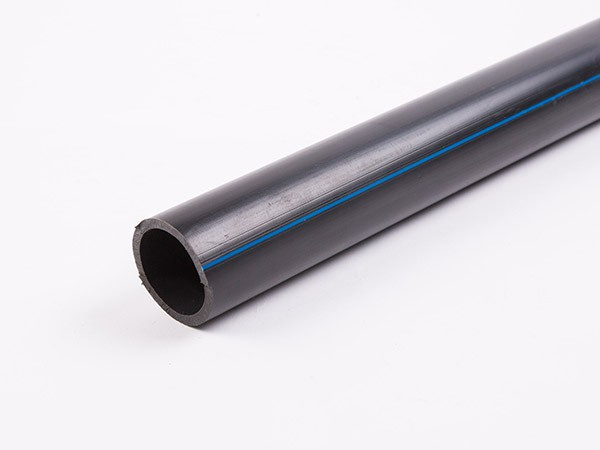

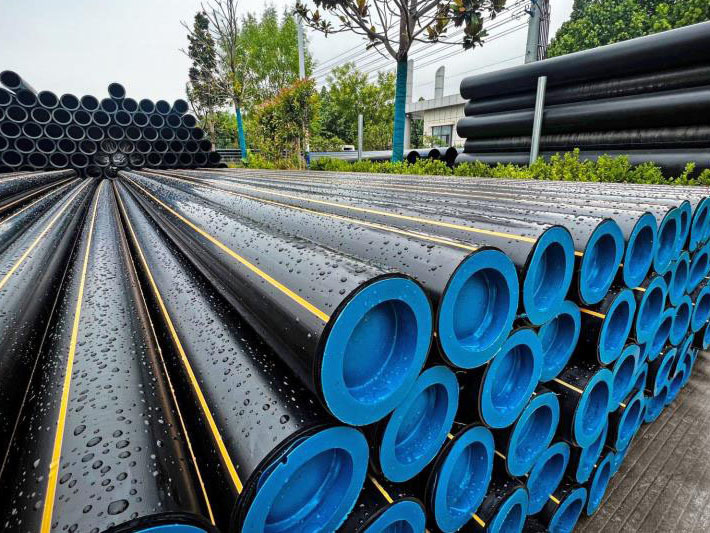

Product display

PE water supply pipe-pe pipe fittings wholesale

There are many connection modes between PE water supply pipe and PE pipe fittings, reducing pipe and metal pipe. Users can choose the appropriate connection method according to the diameter, working pressure, place of use and other environments of the PE pipe. The common connection modes of pe pipe fittings are: hot melt butt connection, electric fusion socket connection, flange connection, steel plastic transition connection, etc.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

There are many connection modes between PE water supply pipe and PE pipe fittings, reducing pipe and metal pipe. Users can choose the appropriate connection method according to the diameter, working pressure, place of use and other environments of the PE pipe. The common connection modes of pe pipe fittings are: hot melt butt connection, electric fusion socket connection, flange connection, steel plastic transition connection, etc.

Hot melt connection: Hot melt connection is a special heating tool used to heat the connection part of PE water supply pipe or pipe fittings under pressure, so that the heating tool can be removed and used after melting. The pressure connects the two fusion faces and maintains them at a steady pressure for a period of time until the joint cools. Hot melt connection includes hot melt butt connection, hot melt socket connection, hot melt saddle connection.

Electrofusion connection: The electrofusion connection is in close contact with the connection part of the PE pipe or pipe fitting and the special electrofusion pipe fitting embedded in the resistance wire. PE pipe is installed by embedded resistance wire. Tubing joint locations are melted and connected until the joint cools. The electrofusion connection can be used for pe pipes of different types and different melt flow rates. Electrofusion connection is divided into electrofusion socket connection and fusion saddle connection.

Flange connection: Flange connection is mainly used for PE water supply pipe and metal pipe or valve, flow meter, pressure gauge and other supporting equipment connection. The flange connection is mainly made of polyethylene (PE), also called flange head. Flange connections, steel or aluminum back pressure sleeve flanges, steel or aluminum flanges, gaskets or sealing rings, bolts, nuts, etc. Flange connection is through the fastening bolts and nuts in close contact with the flange, in order to achieve the purpose of connection.

Steel plastic transition joint: steel plastic transition head connection is to use cold pressing or other prefabricated steel plastic transition joint to connect PE pipe and metal pipe. There are anti-pull locking rings and sealing rings on the steel-plastic transition joint, which are usually required to have good sealing performance, tensile resistance and pressure resistance, and they are larger than the PE pipe in the system.

Previous Page

Next Page

Previous Page

Next Page

Product inquiry