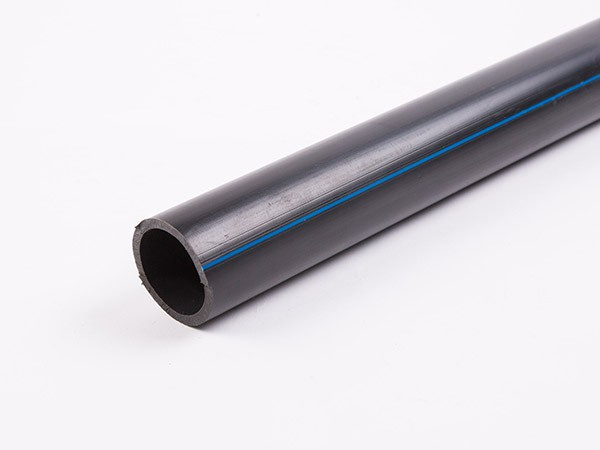

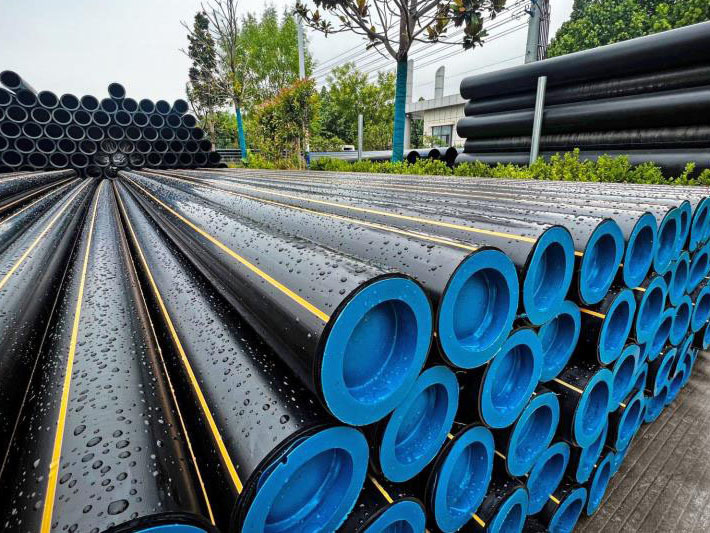

Product display

Shandong PE water supply pipe

PE (polyethylene) material is widely used in the field of water supply pipe manufacturing because of its high strength and corrosion resistance. Because it will not rust, PE water supply pipe is an ideal pipe to replace ordinary iron water supply pipe. PE water supply pipe implementation product national standards: GB/T 13663.1-2017, GB/T 13663.2-2018 "polyethylene (PE) piping system for water supply part 2: pipe".

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

PE (polyethylene) material is widely used in the field of water supply pipe manufacturing because of its high strength and corrosion resistance. Because it will not rust, PE water supply pipe is an ideal pipe to replace ordinary iron water supply pipe. PE water supply pipe implementation product national standards: GB/T 13663.1-2017, GB/T 13663.2-2018 "polyethylene (PE) piping system for water supply part 2: pipe".

China's plastic pipes are developing rapidly and their quality is constantly improving. Among them, PE water supply pipe is widely used in building water supply, building drainage, buried drainage pipe, building heating, gas pipeline, electrical and telecommunication protection casing, industrial pipe, agricultural pipe, etc. It is mainly used in urban water supply, urban gas supply and farmland irrigation and other fields.

Polyethylene is a non-inert material, in addition to a small amount of strong oxidants, can resist a variety of chemical erosion, and not easy to breed bacteria. It is well known that the reason why steel pipes and cast iron pipes are replaced by plastic pipes is not only because plastic pipes have low energy consumption, low energy consumption, light weight, small water flow resistance, simple and rapid installation, low cost, long life, and heat preservation functions. It is also because plastic pipes have better corrosion resistance and are not easy to breed microorganisms than steel pipes and cast iron pipes. The service life of polyethylene pipe is more than 50 years, which has not only been confirmed by international standards and some advanced foreign standards, but also has been proved by practice. Another reason why polyethylene can be widely used is that polyvinyl chloride is increasingly under pressure from environmental protection. The first is the sanitary performance of PVC itself: it is well known that the production of PVC pipes under regular production and strict control can ensure sanitary performance and allow application in the field of drinking water. However, some people are still worried that problems may occur in places where control is not strict: for example, the vinyl chloride monomer in polyvinyl chloride resin exceeds the standard, and toxic additives are misused in the formulation of polyvinyl chloride pipes for water supply. The non-guaranteed drainage with PVC pipes and fittings misused to water supply pipes and fittings. The second is the recycling of PVC pipes: PVC, like polyethylene, is a thermoplastic and can be used in theory. However, it has been proved by various countries that the proportion of old plastic products that can be recycled is limited. The main treatment method is incineration to recover energy. Because PVC contains chlorine, it may produce harmful substances if it is not well controlled during incineration, while polyethylene only contains hydrocarbon and generates water and carbon dioxide after incineration.

Previous Page

Next Page

Previous Page

Next Page

Product inquiry