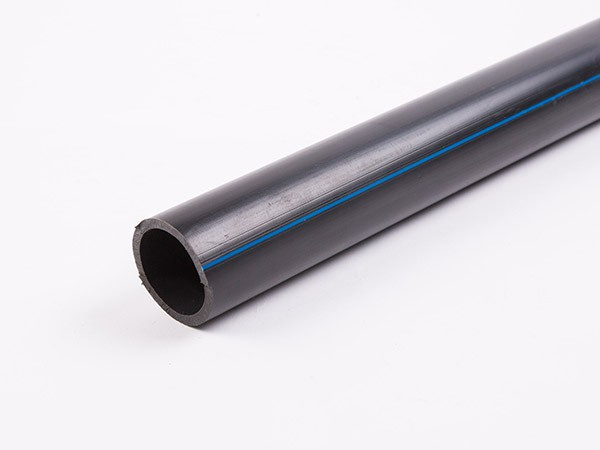

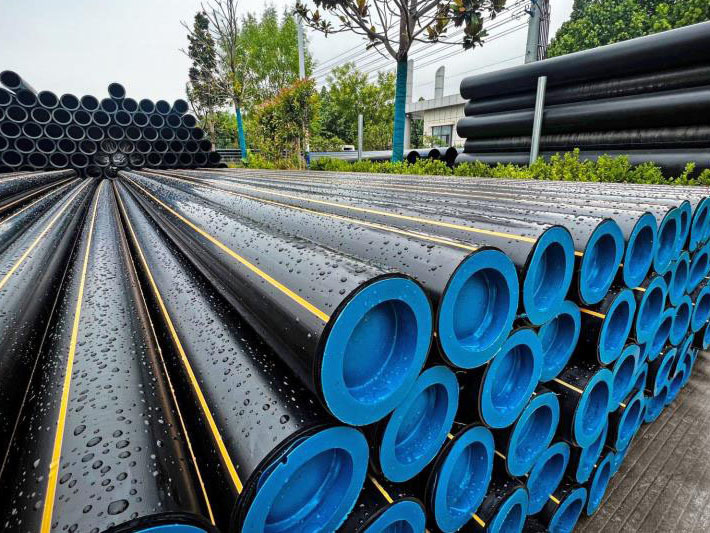

Product display

PE water supply pipe-PE pipe procurement

PE pipeline is widely used in the field. Among them, PE pipeline water supply pipe and gas pipe are two large application markets. PE chemical Chinese name, polyethylene, PE material because of its high strength, high temperature resistance, corrosion resistance and other characteristics, is widely used in the field of water supply pipe manufacturing. Because it does not rust, it is an ideal pipe to replace ordinary iron water pipes.

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

PE pipe is currently China's municipal pipe market, plastic pipe is developing steadily, PE pipe, PP-R pipe, UPVC pipe has a place, of which PE pipe strong momentum of development is remarkable. What is the difference between PE pipe and other commonly used pipes?

PP-R tube

Also called three polypropylene pipe, with light weight, corrosion resistance, no scaling, long service life and so on. PP-R pipe is currently used in the home improvement project more than a water supply pipeline. PPR tube brands are (national authoritative quality inspection products): At present, the common PPR tubes on the market are Zhongcai, Weixing, Jinde, Liansu, Rifeng, etc. There are many PP-R pipe manufacturers, and the quality is different. Once leakage occurs, the loss is huge. It is recommended to choose well-known brand products and choose a professional construction team.

The full name is Polyvinylchlorid, the main ingredient is polyvinyl chloride, and other ingredients are added to enhance its heat resistance, toughness, ductility, etc. The upper layer of this surface film is lacquer, the main component in the middle is polyvinyl chloride, and the lower layer is back-coated adhesive. It is a kind of synthetic material which is popular and widely used in the world today. PE pipe for water supply is the replacement of traditional steel pipe and PVC drinking water pipe.

PE pipeline is widely used in the field. Among them, PE pipeline water supply pipe and gas pipe are two large application markets. PE chemical Chinese name, polyethylene, PE material because of its high strength, high temperature resistance, corrosion resistance and other characteristics, is widely used in the field of water supply pipe manufacturing. Because it does not rust, it is an ideal pipe to replace ordinary iron water pipes.

With the demand for PE pipe, now on the market a variety of PE pipe, many PE pipe is not up to quality standards, so not only affect the use of consumers, but also affect the quality of the project, therefore, identification of PE pipe quality is very important.

Previous Page

Next Page

Previous Page

Next Page

Product inquiry