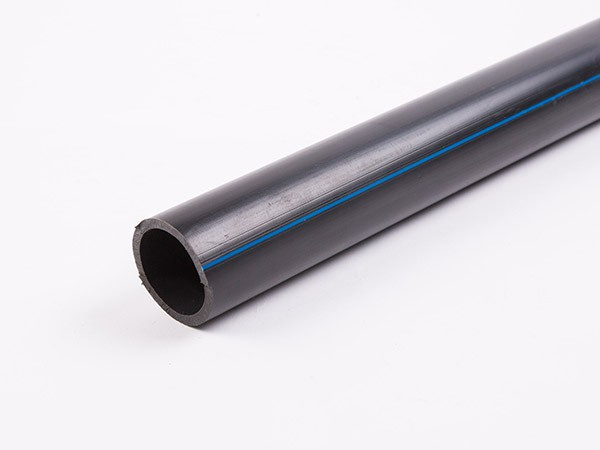

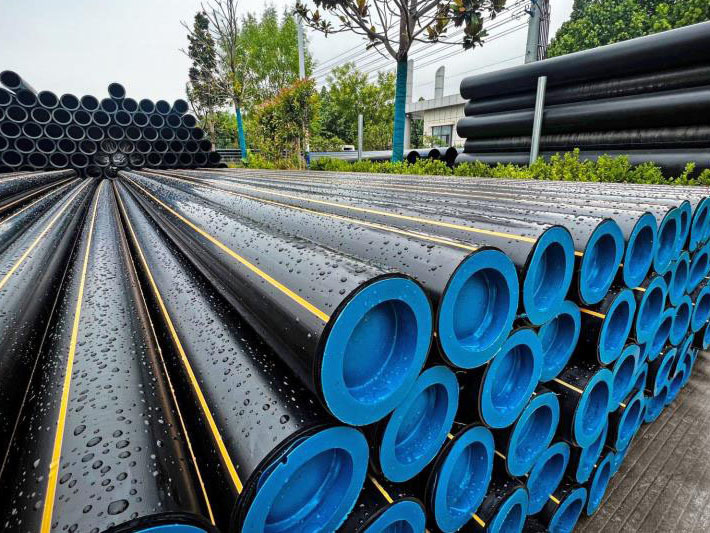

Product display

PE water supply pipe price

PE (polyethylene) material is widely used in the field of water supply pipe manufacturing because of its high strength and corrosion resistance. Because it does not rust, it is an ideal pipe to replace ordinary iron water pipes. PE water supply pipe implementation product national standards: GB/T 13663.1-2017, GB/T 13663.2-2018 "polyethylene (PE) piping system for water supply part 2: pipe".

Classification:

PE water supply pipe

Key words:

Hotline:

Product Description

Polyethylene has unique flexibility and excellent resistance to scratches. The flexibility of polyethylene piping systems has great technical and economic value. The flexibility of polyethylene is an important property that greatly enhances the value of the material for pipeline engineering. The good flexibility allows the polyethylene pipe to be coiled and supplied in longer lengths, avoiding a large number of joints and fittings. At the same time, flexibility and light weight and excellent scratch resistance, so that it can be used to reduce the impact on the environment and social life and cost-effective installation methods, such as excavation-free construction technology. No excavation construction technology refers to the use of a variety of geotechnical drilling technical means, in the surface without ditching (groove) under the condition of laying, replacing or repairing a variety of underground pipeline construction technology. A variety of excavation-free construction techniques are very suitable for the use of polyethylene pipes, such as horizontal directional drilling and guided drilling for laying new pipelines, expanding pipe for replacing old pipelines in situ, interspersing and updating lining for repairing old pipelines, and various improved lining methods (folding deformation method, hot drawing method and cold rolling method). The unique flexibility of PE also allows it to effectively resist underground movement and end loads. On the surface, strength and rigidity, plastic buried pipe than cement pipe and metal pipe, but from the practical application, plastic buried pipe belongs to the "flexible pipe", in the correct design and laying construction of plastic buried pipe is and the surrounding soil to bear the load. Therefore, plastic buried pipes do not need to achieve the same strength and rigidity as "steel pipes" to meet the requirements of mechanical properties in buried use. At the same time, the pressure relaxation characteristics of polyethylene can effectively consume stress through deformation, its actual axial stress level is much lower than the theoretical calculation value, and its elongation at break is generally greater than 500%, and the bending radius can be as small as 20 to 25 times of the pipe diameter. It is a high-toughness material with very strong adaptability to uneven settlement of foundation, these characteristics make it an excellent pipeline to resist earthquakes, foundation settlement and temperature expansion. For example, in the 1995 Kobe earthquake in Japan, PE water supply pipe and gas pipe is one of the spared pipeline system.

PE (polyethylene) material is widely used in the field of water supply pipe manufacturing because of its high strength and corrosion resistance. Because it does not rust, it is an ideal pipe to replace ordinary iron water pipes. PE water supply pipe implementation product national standards: GB/T 13663.1-2017, GB/T 13663.2-2018 "polyethylene (PE) piping system for water supply part 2: pipe".

Previous Page

Next Page

Previous Page

Next Page

Product inquiry