PE Pipe Classification

PE pipe according to the pipe density points: high density polyethylene pipe, medium density polyethylene pipe, low density polyethylene pipe;

PE pipe according to the pipe structure: smooth wall polyethylene pipe, double wall corrugated polyethylene pipe, spiral wound polyethylene pipe;

PE pipe according to the pipe material points: cross-linked polyethylene pipe, aluminum-plastic composite polyethylene pipe, copper-plastic composite polyethylene pipe, steel-plastic composite polyethylene pipe;

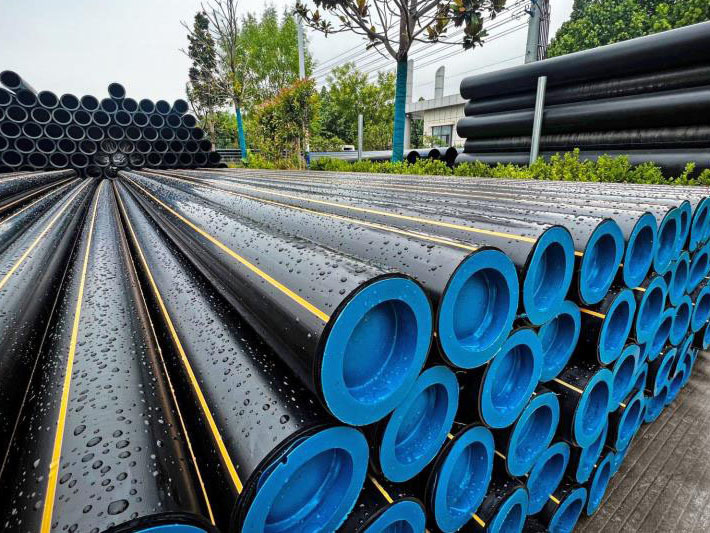

PE pipes are divided into water supply and drainage pipes, gas pipes, electrical casing pipes, agricultural pipes, industrial pipes, hot water heating pipes, and sewage pipes;

PE pipe specification

PE pipe grade: PE32, PE40, PE63, PE80, PE100

Standard size ratio (ratio of nominal outer diameter to nominal wall thickness):SDR26, SDR21, SDR17.6, SDR13.6, SDR11

Nominal pressure (MPa):0.4, 0.6, 0.8, 1.0, 1.25, 1.6

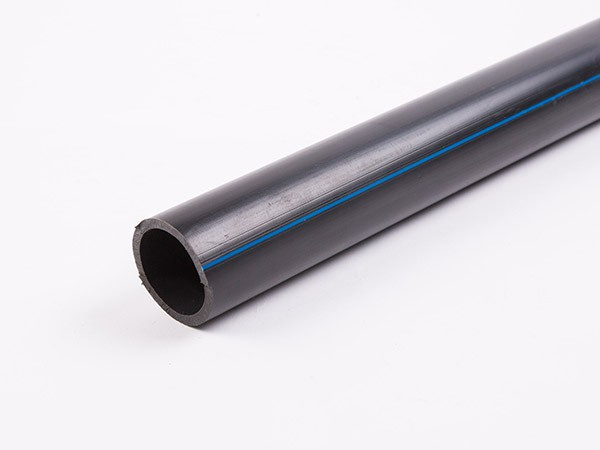

HDPE water supply pipe:

1. Reliable connection: PE pipe systems are connected by electric melting, and the strength of the joint is higher than that of the pipe body.

2, good low temperature impact resistance: PE pipe low temperature embrittlement temperature is very low, can be used safely in the low temperature range. During winter construction, the material will not crack due to its good impact resistance.

3. Good stress cracking resistance: PE pipe has low notch sensitivity, high shear strength and excellent scratch resistance, and its environmental stress cracking resistance is also very prominent.

4, good chemical corrosion resistance: PE pipe can resist the corrosion of a variety of chemical media, the chemical substances in the soil will not cause any degradation of the pipeline. Polyethylene is an electrical insulator, so it does not decay, rust or electrochemical corrosion; in addition, it does not promote algae, bacteria or fungi growth.

5. Aging resistance and long service life: polyethylene pipes containing 2-2.5% evenly distributed carbon black can be stored or used outdoors for 50 years without being damaged by ultraviolet radiation.

6, good wear resistance: PE pipe and steel pipe wear resistance comparison test shows that the wear resistance of PE pipe is 4 times that of steel pipe. In the field of mud transportation, compared with steel pipes, PE pipes have better wear resistance, which means that PE pipes have a longer service life and better economy.

7, good flexibility: the flexibility of PE pipe makes it easy to bend, engineering can bypass obstacles by changing the way of pipe direction, in many occasions, the flexibility of the pipe can reduce the amount of pipe fittings and reduce installation costs.

8. Low water flow resistance: PE pipe has a smooth inner surface, which has a higher conveying capacity than traditional pipe, and also reduces the pressure loss of the pipeline and the energy consumption of water delivery.

9, easy to handle PE pipe than concrete pipe, galvanized pipe and steel pipe lighter, it is easy to handle and install, lower manpower and equipment requirements, means that the installation cost of the project is greatly reduced.