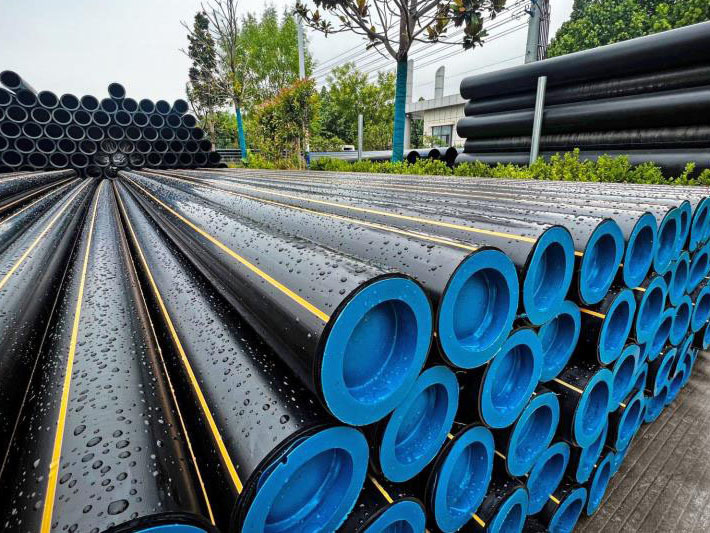

Product display

PE pipe steel wire mesh skeleton

Products have been widely used in environmental protection, papermaking, metallurgy, electric power, mining, chemical fiber, petrochemical, sulfuric acid, chlor-alkali, pharmaceutical, salinization, landfill and sewage treatment and other fields.

Classification:

PE steel wire mesh skeleton pipe

Key words:

Hotline:

Product Description

Steel wire mesh skeleton plastic composite pipe is an improved new type of steel skeleton plastic composite pipe. This pipe is also called srtp pipe. This new type of pipe is made of high-strength over-plastic steel wire mesh skeleton and thermoplastic polyethylene as raw materials, steel wire wound mesh as polyethylene plastic pipe skeleton reinforcement, high-density polyethylene (HDPE) as the matrix, using high-performance HDPE modified bonding resin to the steel wire skeleton and inner and outer high-density polyethylene tightly connected together, so that it has excellent composite effect. Because the high-strength steel wire reinforcement is encased in a continuous thermoplastic, the composite pipe overcomes the respective disadvantages of the steel pipe and the plastic pipe, while maintaining the respective advantages of the steel pipe and the plastic pipe.

The steel wire mesh skeleton plastic composite pipe adopts high-quality materials and advanced production technology to make it have higher pressure resistance. At the same time, the composite pipe has excellent flexibility and is suitable for long-distance buried water supply and gas pipeline systems. The pipe fittings used in the steel wire mesh skeleton polyethylene composite pipe are polyethylene electrofusion pipe fittings. When connecting, the outer plastic of the pipe and the inner plastic of the pipe are melted by the heating element inside the pipe, and the pipe and the pipe are reliably connected together.

Product Features

1. Overcome the rapid stress cracking phenomenon of plastic pipes. Because the structure of steel and plastic materials is compounded, the rapid stress that is difficult to overcome for plastic pipes will not occur.

2. It has the strength, rigidity and impact resistance of more than ordinary pure plastic pipes, and is similar to the low linear expansion coefficient and creep resistance of steel pipes;

3. Light weight, easy to install, pipe connection using electric melting joints, anti-axial tensile ability, connection technology is mature and reliable, pipe variety specifications developed, can be connected with other various pipelines, valve equipment;

4. Double-sided anti-corrosion, with the same anti-corrosion performance as plastic pipes, and the use of high temperature and corrosion resistance, low thermal conductivity:

5. Excellent structure, the reinforced skeleton of the pipe and the inner and outer plastic are contained into a whole, and there is no worry of peeling off the inner and outer plastic and the reinforced body;

6. The inner wall is smooth and does not scale. The water head loss of pipe type is 30% lower than that of steel pipe. 6

7. The whole pipe is designed according to the service life of 50 years;

8. By adjusting the diameter of the steel wire, the thickness of the plastic layer, etc., to manufacture pipes of different pressure levels 8

Application areas

Steel wire mesh skeleton plastic composite pipeline is a new type of pipeline with excellent performance, which is widely used in oil fields, power plants, chemical and petrochemical enterprises, water companies, municipal gas, seawater utilization pipelines and other fields. Executive standard: GB/T 32439-2015

Product inquiry